Introduction

In aquaculture—whether fish ponds, shrimp farms, biofloc systems, or recirculating systems—maintaining adequate dissolved oxygen (DO) is vital for healthy growth, survival, and feed utilization. Poor aeration can lead to stress, disease, or mass mortality events. But how much aeration is “enough”? That’s where a tool like the AirOxi Aeration Calculator becomes invaluable for aqua farmers.

In this post, we’ll explore:

- What the AirOxi Aeration Calculator is

- Key parameters and how it works

- Benefits for aquaculture operations

- Practical tips and caveats

- A sample use case

What Is the AirOxi Aeration Calculator?

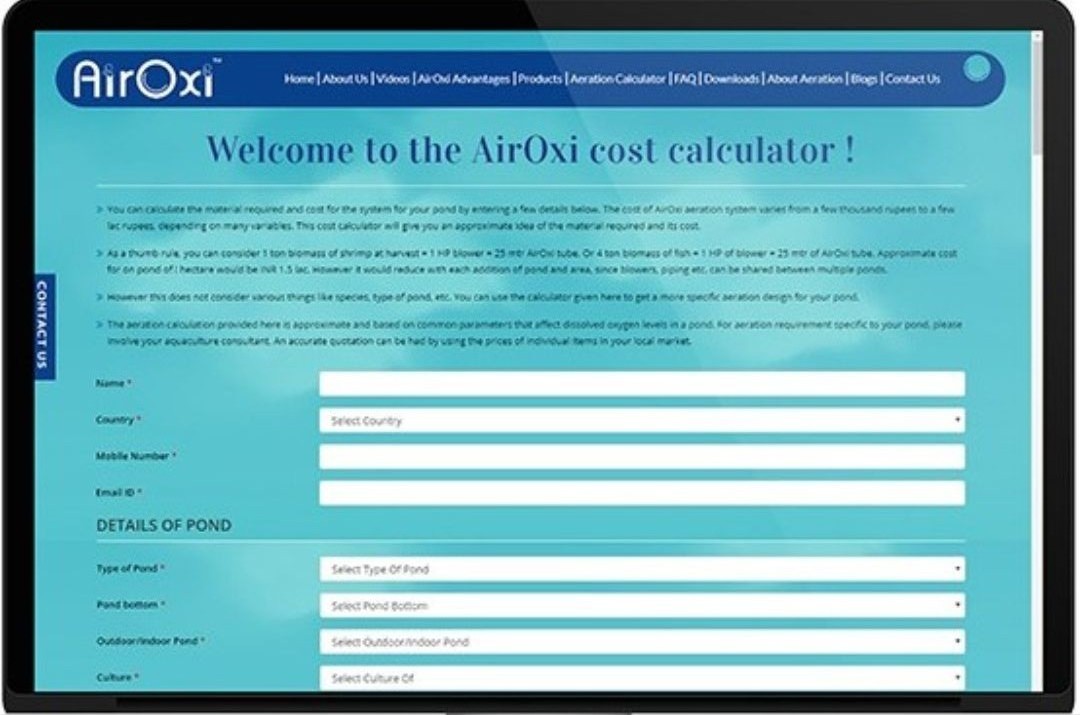

The AirOxi Aeration Calculator is an online tool (hosted at airoxi.com/calculator) that helps estimate the material requirements and cost of an aeration system tailored to your pond or farm’s conditions. (airoxi.com)

Instead of relying purely on rules of thumb or guesswork, farmers input a few relevant parameters (pond size, salinity, design preferences, species, etc.), and the calculator outputs an estimate of the blower size, aeration tube length, piping, and cost. (airoxitube.com)

Thus, it simplifies the design and budgeting of an aeration system suited to your farm’s specific needs. More info https://airoxitube.blogspot.com/2020/10/want-to-calculate-material-and-cost-of.html

Key Inputs & How the Calculation Works

The accuracy and usefulness of the calculation depend on the inputs. Some of the important parameters considered include:

| Parameter | Role in Aeration Design |

| Pond/tank size (area, depth) | Determines the volume of water to be oxygenated |

| Stocking density / biomass | Larger biomass demands more oxygen |

| Species (fish vs. shrimp) | Different species have different oxygen needs |

| Salinity / water type | Salinity affects oxygen solubility and transfer efficiency |

| Aeration design choice | Whether you want diffused fine bubble aeration, tube layout, blower type |

| Temperature / water quality factors | Affects oxygen demands and system inefficiencies |

Based on these, the calculator estimates:

- The blower horsepower (HP) required

- The length or number of aeration tubes

- Piping, fittings, and peripherals

- An approximate cost of the aeration setup (airoxitube.com)

As a guideline, AirOxi literature suggests “1 ton biomass of shrimp = 1 HP blower + 25 m of AirOxi tube,” or “4 ton fish biomass = 1 HP + 25 m tube,” though those are rough rules and the calculator refines it based on actual conditions. (airoxitube.com)

Benefits to Aqua Farmers

Using a well-designed aeration system—and designing it well—can provide multiple advantages:

- Optimized Investment

Instead of over-dimensioning (wasting money) or under-dimensioning (risking oxygen shortage), the calculator guides you to a balanced design.

- Energy & Cost Savings

Because AirOxi’s diffused fine-bubble systems tend to be more efficient (higher Standard Oxygen Transfer Rate, SOTR) than paddlewheel or surface aerators, farmers report electricity savings. (airoxi.com)

For example, in AirOxi’s comparisons, their aeration system might require only 5 HP per hectare, versus 16 HP (with paddle wheels) for similar biomass support. (airoxi.com)

- Better Production Capacity

With reliable oxygen delivery, you can push stocking density higher (within biological limits) with lower risk of oxygen stress.

- Quicker Design Planning

New or scaling farms need not reinvent the wheel—this tool accelerates aeration planning without waiting for multiple vendor quotes.

- Risk Reduction

Under-aeration causes low DO zones (especially at night), potentially leading to fish/shrimp mortality. The calculator helps you identify safe margins.

- Predictability & Transparency

When you present funding or get supplier quotes, you have a baseline design and cost estimate to validate or negotiate against.

Practical Tips, Challenges & Caveats

While the calculator is powerful, here are some real-world points to consider:

- Accuracy depends on input quality: Incorrect depth, biomass, or species info leads to misleading output. Always cross-check field data.

- Local costs & parts vary: The cost estimate may not fully capture local labour, shipping, or tax costs.

- Allow for safety margin: It’s wise to over-spec a little (e.g. 10–20%) rather than run at the edge.

- Maintenance & efficiency degradation: Fouling, clogging, wear and tear reduce performance over time—factor in periodic maintenance.

- Supplemental aeration: In extreme conditions (heat, algal bloom crashes), you may need backup sources (like paddlewheels or emergency aerators).

- Consult experts: For large farms or high-risk design, use the calculator as a guide and validate with an aquaculture engineer.

Sample Use Case

Let’s imagine a shrimp farm scenario:

- Pond area: 1 hectare

- Average depth: 1.2 m

- Target biomass: 4 tons shrimp

- Salinity: moderate

- Preference: fine bubble diffused aeration

You input these into the AirOxi calculator and get an estimate:

- Blower: 1.8 HP

- Tube length: 50 m (two 25 m lines)

- Piping + fittings

- Estimated cost: ₹1,50,000

You compare this to a vendor quote (₹1,60,000) and use it to negotiate or refine design layout. You also simulate backup scenarios (e.g. if biomass increases, temperature rises) and choose to increase blower margin to 2 HP.

During farm operation, you monitor DO levels and ensure the aeration performs as predicted.

Conclusion & Call to Action

The AirOxi Aeration Calculator is a practical, value-adding tool for aquaculture farmers looking to design efficient, cost-effective aeration systems. It bridges the gap between empirical guesswork and precise engineering, giving you confidence in planning, budgeting, and system performance.

If you’re an aqua farmer or planning a new farm, try visiting the calculator at airoxi.com/calculator and use it as your starting point. Pair that with ground-level measurements, expert review, and field monitoring to get the best outcomes.

📞 Need Help Choosing?

AirOxi expert team is always ready to guide you in selecting the best aeration tube for your farm. Contact us today for a customized recommendation! More info visit: www.airoxi.com

+917041004098

WhatsApp us

WhatsApp us

Leave A Comment